The UV printer technology involves using an ultraviolet light during printing to dry or cure the ink. The UV ink also contrasts with the traditional printing in that the ink instantly cures in the presence of the UV light rendering it to be easily used on. Surfaces such as glass, metal, wood, and plastic are all available. This high technology process produces crisp images and vivid colours in quick time.

Consider the possibility to print on virtually anything: phone covers, acrylic, leather, even tiles, without a special coating. That is why UV printers are so thrilling. Innovation is in the area of marketing and design since businesses are now able to customize products within a short period and in a high-quality manner.

Here in this blog, you will learn how UV printing works, what its differences with the old methods are, and why it is rapidly being considered the future of printing in all industries.

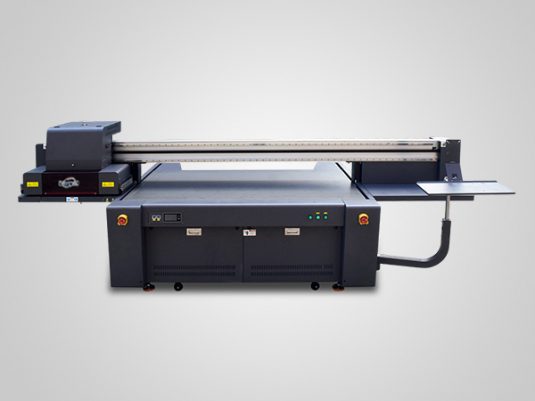

Understanding UV Printer Technology

UV printers are printers which dry or cure ink using ultraviolet (UV) light as the ink is being printed.. It enables printing on many surfaces, including glass, acrylic, metal, wood and plastic. The UV printers, unlike traditional printers, have special UV inks that dry rapidly under light, which avoids smudging and produces bright, crisp prints.

Technology is transforming the manner in which the business prints promotional materials, signs, and packaging among others. UV printers are flexible and fast, whether you want to print phone covers or large-format banners, the older printers can never compete. It is a real game changer to small businesses and big industrial activities.

How UV Printer Technology Works

UV LED curing system is used immediately after UV ink is applied to any surface. This light dries the ink in milliseconds and it binds with the material. It does not have to dry, nor is there any chance of ink bleeding or spreading.

This technique allows direct-to-substrate printing, that is, you can print directly on the objects without transfer papers or other coating. The outcome is a smooth professional appearance on rigid and flexible substrates.

The Components of a UV Printer

A UV printer has a number of important components that interact to yield quality prints. The spraying print head is made to be very precise and durable. The UV LED curing system takes its place right behind to dry the ink once it is placed.

The other components are the ink reservoirs, a bed or belt system to transport the object or material and design layout management software. When these parts are integrated, they allow digital flatbed printing or wide format UV printing, depending on the model.

The Evolution of UV Printer Materials

Previously printing was restricted to paper and selected treated surfaces. Now, with high-performance UV inks and better adhesion processes, you can print on virtually any surface.Leather, wood, glass, metal, and plastic are all in the mix.

This growth has opened new avenues of customizing products and printing industrial signs. UV flatbed printers have been creating unbelievable versatility with little to no preparation time whether you are printing directly onto round bottles or flat panel.

Benefits of Using UV Printer Technology

A major advantage of UV printing over traditional printing is its flexibility. You do not have to use flat and porous materials. UV printers can print everything between custom promotional products and more complicated industrial uses.

They are also quite fast.No drying time is required, no smudges, and less production error. No wonder why more companies are moving towards UV inkjet printers in order to save time and money.

Excellent Print Quality

UV Printers produce high definition prints with tremendous depth. Because the ink cures instantly it does not spread or soak into the material. That means neater lines, deeper colors, and snappier text.

You are also provided with special effects such as white ink UV printing and multi-layer UV printing that enables you to have embossed or 3D-like designs. This qualifies them to be used in luxury packaging, labels and custom branding.

Versatility

UV printers have a massive advantage as they can print on acrylic, glass, and metal and even uneven surfaces.Interested in printing on corrugated wood panels or curvy bottles?

This flexibility qualifies them to be used in such industries as décor, electronics, packaging, and personalized gifts. UV prints are very durable when the surface is smooth or rough.

Durability and Longevity

UV technology produces durable prints. They are fade, scratch and moisture resistant due to instant ink curing. That would be particularly crucial in cases of the products that are exposed to the sun or severe conditions.

In addition many UV prints are weather resistant which makes them perfect for outdoor signage or industrial labels. Your prints don’t only look great, they last.

Eco-Friendly Option

UV printers do not release toxic VOCs (volatile organic compounds) into the air. No heat is involved and the ink is less toxic to the planet than solvent based methods.

In addition, since prints dry up immediately, the wastage is minimal or non-existent. This makes the green UV printing a sustainable option to business-minded people who love the planet.

Quick Turnaround Time

UV printing gives you time. In a few minutes you can go digital design to finished product. No drying time, no protective coating needed and less setup delays.

The fast drying printing technology is suitable in fast moving production lines or in small companies that have bulk orders. You will have to face strict deadlines and not compromise on quality.

Key Features of DTF UV Printers

UV printing Direct-to-Film (DTF) is very beneficial. Among the most prominent features is the fact that they can be printed on special transfer films that can be transferred to a wide range of surfaces.

The other important aspect is that they have an instant ink curing process. The ink is cured by UV LEDs, so it does not dry. They are also capable of printing with white ink, thus bright designs on dark or transparent backgrounds.

Advanced Printing Technology

As a result of modern printing, the way we print has changed. It prints faster and of high quality using smart machines and modern techniques. Plastic, metal, glass, and fabric have all been printed with printers.

The precision and cleanliness of the prints are one of the big benefits.The details are more detailed, and the colors are more vivid.. Certain printers such as UV and DTF can even print on a curved or uneven surface. Older machines could not allow this kind of quality and flexibility.

Software Compatibility

DTF UV printers are compatible with most of the design and print software packages. They are usually compatible with programs such as Adobe Photoshop, Illustrator and RIP software that help to control color, layers and print parameters.

You can also manage the ink consumption, resolution and even special effects such as white ink layers or varnish in the software. The system can be easily learned within a short period even by novices with user-friendly interfaces. Compatibility of software will be good and will give better results in printing.

Cost-Effective Printing Solutions

DTF UV printers are a cost-effective solution to print high-quality without investing too much in materials or in the installation. They require neither screens, plates nor special coatings, saving not only time but also money. This is why they are a perfect match to small companies and bespoke product makers.

Since the ink does not take time to dry, there is reduced wastage and reprinting of pages because of smudges or misalignment. Small runs can be printed without incurring high costs and therefore on-demand orders can be managed easily. In few words, they can make you achieve professional results without breaking your budget.

Frequently Asked Question

What is the purpose of the print head of a UV printer?

The print head is an ultra-precise spray of UV ink on the material, which makes the print sharp and detailed.

What is the UV LED curing system?

The UV light cures or dries the ink instantly, so there is no smudging and printing is faster.

Ink may be printed white or clear on a UV printer?

Well, most UV printers can accommodate additional ink cartridges of white ink and clear varnish.

Which surfaces can the flatbed system work with?

The rigid, flexible materials such as glass, metal, plastic, wood, and even curved objects can be placed on the flatbed or conveyor.

Does UV printer require cooling?

Yes, the cooling system provides the safe and smooth work of UV LEDs and internal components

Conclusion

Knowing the elements of a UV printer, you will be able to understand why this technology is so powerful and versatile. Every component contributes to the fast and high-quality prints; whether it is the accuracy of the print head or the immediate drying UV LED curing system..

UV printers are designed to print on flat, rigid and curved surfaces, whatever your application, UV printers are designed to make the task easy. They are well designed, their software is sophisticated and their hardware is durable to meet the needs of creative and industrial printing.

Meta Description

Explore the key components of a UV printer and how they work together to deliver fast, high-quality printing on various materials and surfaces.